CAPACITY

ABILITY

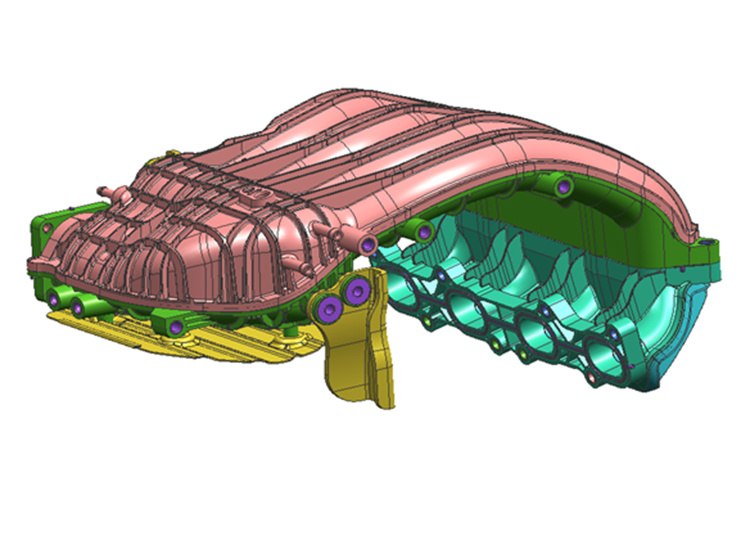

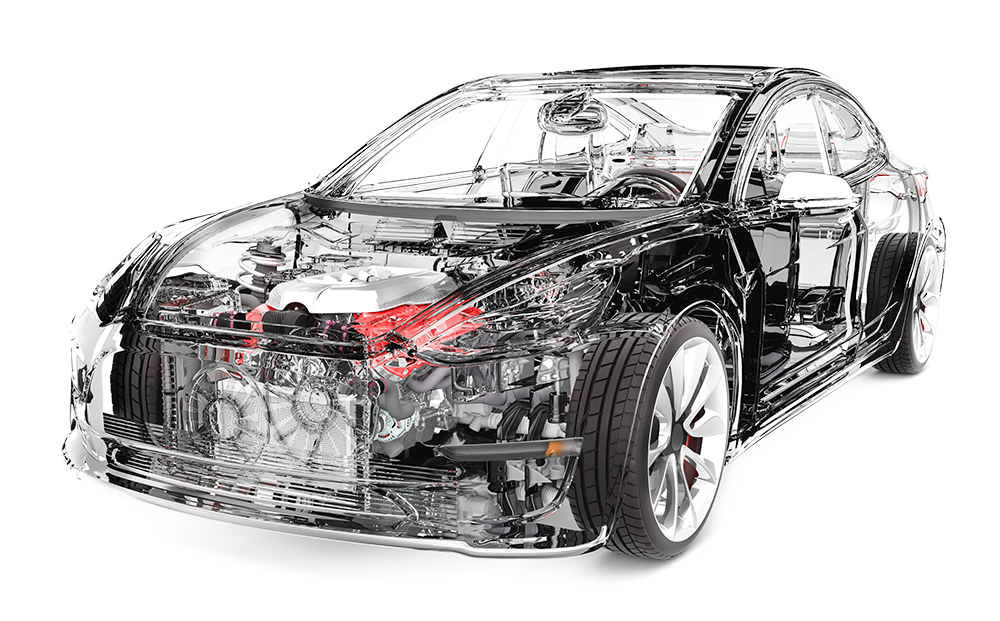

Product Design

Our core team have the positive ability to make the design for the engine plastic part. We can make the analysis with CAE and CFD for the strength、vibration modal、noise 、flow analysis、oil gas separation etc. we can also associate with our customer for new product development based on more than 50 projects experience for Intake manifold 、engine cylinder cover、oil pan、water tank、air tank etc.

Mold manufacturing

Zeit has a team with 70 persons for mould design and manufacturing. We can make the commercial and internal use mould at the same time.

When we got the export moulds from the world first class company, our mould experience and quality level was improved greatly from their training and guiding. Meanwhile the internal mould developing capability also make our own production project to go smoothly.

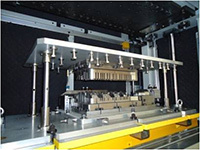

Tooling equipment

our special equipment & fixture division can make the design and manufacturing the equipment for welding model、cold plug、hot plug 、air leakage test、blasting experiment etc.

Production

Zeit established the Production Division by strong development capability in 2011 in order to meet our future development. Meanwhile we start to entre the field for auto plastic part matching production special for the engine plastic parts. We get the recognition from our customer and become the First-Tire suppliers by the advanced technology 、stable quality and good service.

Service

With yearly building chain from part design 、mould manufacturing、tooling and fixture 、Non-standard equipment、part production, we can provide the turnkey project and one stop service

The available service :

■ Part design

■ Rapid sample manufacturing

■ mould development

■ welding model development

■ cold and hot plug equipment、function test equipment (including the air leakage test and blasting experiment)

■ limited-run

■ batch production